How to Inspect a Winch Strap for Damage

When inspecting a winch strap for damage, what you are really inspecting is a "tie-down system." Each tie-down system component must be in compliance with federal, state, and provincial requirements. If any component is not in compliance, the complete tie-down must be removed from service immediately.

Drivers should inspect four main components of a winch strap before putting them into service:

- The Webbing

- The Sew Pattern

- The Ratings and Markings

- The End Fittings

Should you question the integrity of any of these components, take the winch strap out of service.

Now, let’s go over the out of service criteria for each of the four main components:

1) Out of Service Criteria for Winch Strap Webbing

- Holes, tears, cuts, snags, or embedded particles that cast doubt on the strength of the winch strap tie-down.

- Broken or worn stitching in load-bearing stitch patterns.

- Abrasion wear.

- Knots in any part of the webbing.

- Heat damage.

- Melting, charring, or weld splatter on any part of the webbing.

- Illegible or missing tags or no stencil.

2) Out of Service Criteria for the Sew Pattern

If the sew pattern shows any signs of broken or worn stitching, the winch strap tie-down must be removed from service. The sew pattern is a pattern for sewing the end fitting to the webbing. The Kinedyne sew pattern is engineered and designed to match the style and makeup of the webbing, as well as the end fitting being used.

The sew pattern is very important to the overall integrity of the winch strap, as the synthetic webbing is weakened each time it is pierced by a needle. There is a fine line between too much of a sew pattern and not enough – you can be assured that Kinedyne gets it just right!

Another important aspect of the sew pattern is the fold-over. It must be long enough to provide an ample sew pattern. Note: The industry standard fold-over is a minimum of 5.5 inches.

3) Out of Service Criteria for Ratings and Markings

A winch strap without the proper ratings and markings may be deemed out of service or downgraded depending on federal, state, or provincial regulations.

For a working load limit tag to comply, it must be marked with the manufacturer’s name and the working load limit in both pounds and kilograms. Kinedyne uses an extremely durable Tyvek material for its WLL tags.

In addition to the tag, Kinedyne pioneered stenciling the working load limit directly onto the winch strap. If the working load limit tag gets torn off or fades, the stencil keeps your winch strap in compliance.

4) Out of Service Criteria for End Fittings

An end fitting, tensioning device, or other hardware is another key component of a winch strap tie-down, as it secures the winch strap to the trailer.

If it is broken, bent, twisted, or has a significant nick or gouge or a visible crack, the winch strap tie-down must be removed from service immediately.

When to Inspect

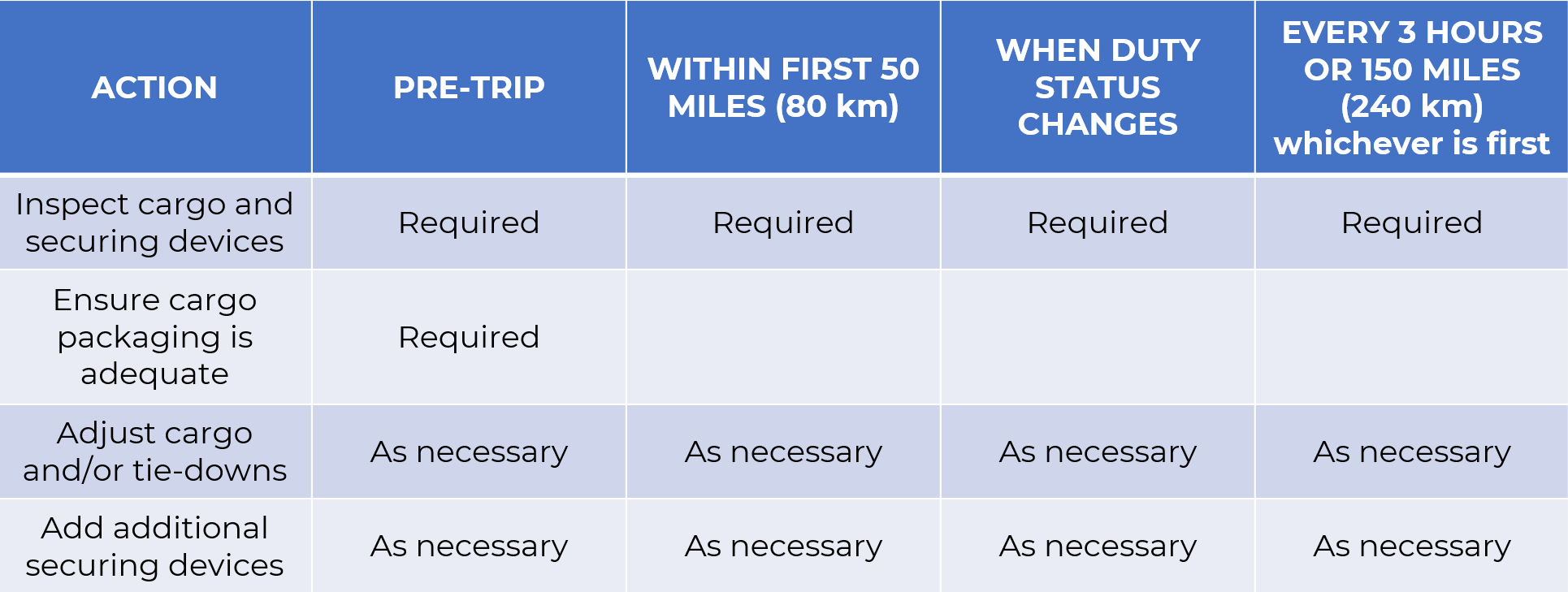

The driver must inspect cargo securement including winch straps and tie-down components at certain intervals and make any necessary adjustments to stay in compliance. In general, those intervals are: pre-trip; within the first 50 mi/80 km; when duty status changes; and every 3 hours or 150 mi/240 km, whichever comes first. See the chart below for more details.

Learn More

For more information about inspecting winch straps and other tie-down components, watch our How to Inspect a Winch Strap 201 video. This video is part of the Kinedyne Education Series of introductory videos designed to teach the basics of cargo control products – what they are, what they are used for, how to choose the right tools for the job, and more. To view more Kinedyne videos, click here.

US Dollars

US Dollars

CA EN

CA EN

MX ES

MX ES